- After Cooler

- Oil Cooler

- Refrigerated Oil Cooler

- Agricultural & marine dryer

- SKAP

- Medical equipment casing

- Heat treatment conveyor

- Screen exposure

- Screen printer

JINYANGTECH

PRODUCT

PRODUCT

l Product l After Cooler

AFTER COOLER

JinyangTech is leading the industry with advanced technology and know-how

Overview

Moisture in air compressors degrades the quality and shortens the life time of various pneumatic devices and industrial sites. Thus removing moisture from compressed air and decreasing its temperature is very important. These products are requisite accessories for pneumatic systems, which freeze hot and humid compressed air and then efficiently condense and remove moisture to provide air at a constant temperature.

Features

- Simple to install and maintain without coolant

- Excellent heat transfer area ensures superior cooling effect

- Consists of pure autumn fins and tubes to maximize cooling efficiency

- Multi-circuit design minimize pressure drop in heat exchangers

- The cases are made of special high-temperature-treated powder-painted steel plates for the solid and smart design

- Stable operation with accurately balanced cooling fans and low frequency motors

Installation

1. Where to install

- places where it is easy to wire from power supply

- places where the ground stable and horizontal

- places where it is easy to check and maintain oil coolers

2. For outer installation

- places not exposed to direct sunlight

- places not exposed to rain and snow

- places where the surrounding temperature is above zero degree

3. How to connect the pipes

- Use two pipe wrenches when connecting the pipes.

- Make sure not to damage the cases or pipes while piping.

- Be careful not to bend the pipes for high pressure hoses.

- Extend the pipes to the outlets so that a significant amount of water will be drained.

4. Cautions for piping

- Connect pipes that will fit the size of the air inlets and outlets.

- Make sure that the vibration of the air compressor will not transfer tho the oil cooler.

- Make sure that weight of the pipes will not exceed that rated load of the air cooler.

5. Inappropriate places for installation

- places directly exposed to the elements(e.g., rain, snow, wind)

- places that are humid, full of dust or powder, or narrow

- places where there vibrations or where the surrounding temperature is bellow zero degree

6. Wiring and construction

- Wiring requires connection to the power supply and ground.

- The ground should be third class.

- Perform wiring only after ensuring that the power of the oil cooler is off.

Operation

1. Operation and checking

Be sure to checked the following before conducting test operation:

≫ Checking each part

-Is there any defect in the installation places, piping, and wiring?

-Are the stop valve closed in the bypass pipes?

-Are the stop valve installed on the outlets pipes closed?

≫ Checking the power supply

-Is the voltage normal?

-Is it exactly grounded?

≫ Operation procedure

-Press the power switch

-Check if the power switch is on and if the fan motors works

2. Maintenance of the coolers

≫ Always remove the dust or any foreign material on the condensers(heat exchangers) to enhance the efficiency and

extended the life of the air cooler.

≫ Check the connection of the wiring to prevent damaged to the motor on account of broken wires for the three-phase

power supply.

≫ If the oil cooler will not be used for a long time at below-zero-degree temperature, opened the drain valve to prevent it

from bursting.

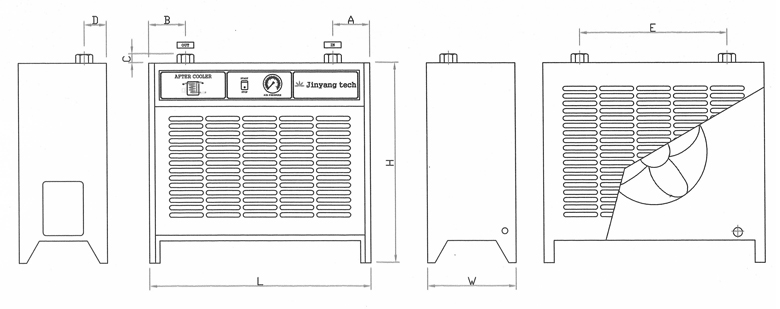

Air cooler specification

| Model | DIMENSION (mm) | IN OUT | Handling flow (Nm³/min) |

Power supply (v/ph/Hz) |

Weight (kg) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | A | B | C | D | E | |||||

| JY-10Hp | 490 | 270 | 545 | 47.5 | 47.5 | 10 | 65 | 395 | 20A | 2.2 | 220v/1ph 60Hz, 50Hz |

23 |

| JY-20Hp | 577 | 300 | 582 | 48.5 | 48.5 | 10 | 65 | 480 | 25A | 3.3 | 25 | |

| JY-30Hp | 738 | 300 | 690 | 86.5 | 86.5 | 10 | 65 | 565 | 40A | 5.2 | 35 | |

| JY-50Hp | 1070 | 350 | 765 | 82.5 | 82.5 | 25 | 120 | 905 | 50A | 8.0 | 69 | |

| JY-75Hp | 1270 | 400 | 840 | 92.5 | 92.5 | 25 | 120 | 1085 | 65A | 12.7 | 220v~380v 3ph/60Hz, 50Hz |

103 |

| JY-100Hp | 1450 | 400 | 990 | 95 | 95 | 25 | 120 | 1260 | 80A | 17.5 | 128 | |

| JY-150Hp | 1750 | 470 | 1235 | 95 | 95 | 25 | 120 | 1560 | 80A | 21.5 | 228 | |

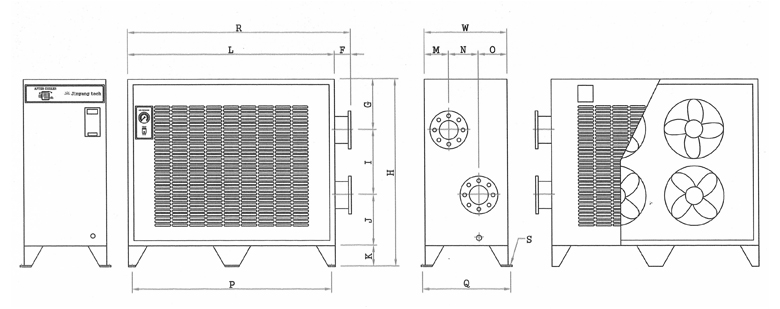

| Model | DIMENSION (mm) | IN OUT | Handling flow (Nm³/min) |

Power supply (v/ph/Hz) |

Weight (kg) |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | W | H | F | G | I | J | K | M | N | O | P | Q | R | S | |||||

| JY-200Hp | 1750 | 560 | 1235 | 100 | 320 | 350 | 320 | 245 | 140 | 140 | 280 | 1645 | 570 | 1850 | 4-ø16 | 100A | 31.0 | 220v~380v 3ph 60Hz,50Hz |

248 |

| JY-300Hp | 1830 | 560 | 1385 | 100 | 370 | 400 | 370 | 245 | 140 | 140 | 280 | 1725 | 570 | 1930 | 4-ø16 | 100A | 47.5 | 273 | |

| JY-400Hp | 2150 | 650 | 1415 | 150 | 357.5 | 500 | 357.5 | 200 | 150 | 175 | 325 | 2045 | 680 | 2300 | 4-ø16 | 125A | 62.0 | 323 | |

| JY-500Hp | 1950 | 650 | 1573 | 150 | 386.5 | 600 | 386.5 | 200 | 140 | 190 | 320 | 1845 | 680 | 2100 | 4-ø16 | 150A | 77.0 | 378 | |

| JY-600Hp | 1950 | 650 | 1688 | 150 | 394 | 700 | 394 | 200 | 140 | 190 | 320 | 1845 | 680 | 2100 | 4-ø16 | 150A | 95.0 | 393 | |

| JY-700Hp | 2000 | 650 | 1764 | 150 | 382 | 800 | 382 | 200 | 140 | 190 | 320 | 1895 | 680 | 2100 | 4-ø16 | 150A | 105.0 | 425 | |

| JY-800Hp | 2050 | 650 | 1878 | 150 | 389 | 900 | 389 | 200 | 140 | 190 | 320 | 1945 | 680 | 2200 | 4-ø16 | 150A | 120.0 | 470 | |

| JY-900Hp | 2150 | 700 | 1878 | 150 | 389 | 900 | 389 | 200 | 140 | 190 | 370 | 2045 | 730 | 2300 | 4-ø16 | 150A | 130.0 | 550 | |

| JY-1000Hp | 2300 | 750 | 2030 | 150 | 465 | 900 | 465 | 200 | 140 | 242 | 368 | 2195 | 830 | 2450 | 4-ø16 | 200A | 145.0 | 580 | |

| JY-1200Hp | 2400 | 800 | 2030 | 150 | 465 | 900 | 465 | 200 | 150 | 242 | 408 | 2295 | 830 | 2550 | 4-ø16 | 200A | 180.0 | 600 | |

* Note: Handling flow is based on the ambient temperature 20℃, inlet air temperature 70℃, inlet air pressure 7.0Kgf/cm2